Excellent performance

Good stiffness, high impact properties at room and sub-zero temperatures, good dimensional stability, water and chemical resistant.

Moplen EP490H is a heterophasic copolymer specifically developed for foam applications, providing customers and converters with a monomaterial solution

Moplen EP490H exhibits:

High foamability for a light-weight final product, which uses less plastic

High impact properties at room and sub-zero temperatures

Outstanding creep and deforming resistance

High stiffness

Good dimensional stability

Monomaterial solution

Food packaging

Rigid packaging

Consumer goods

Extruded foamed sheets

Thermoforming

Extrusion blow moulding

Ideal for food and rigid packaging.

Moplen EP490H exhibits:

High foamability for a light-weight final product, which uses less plastic

High impact properties at room and sub-zero temperatures

Outstanding creep and deforming resistance

High stiffness

Good dimensional stability

Monomaterial solution

Food packaging

Rigid packaging

Consumer goods

Extruded foamed sheets

Thermoforming

Extrusion blow moulding

Ideal for food and rigid packaging.

Click and drag to compare

A unique combination of foamability and thermoformability is now possible:

Moplen EP490H has a higher foamability than any conventional polypropylene. It has a high melt strength and is suitable for the extrusion of foamed sheets, which are then thermoformed.

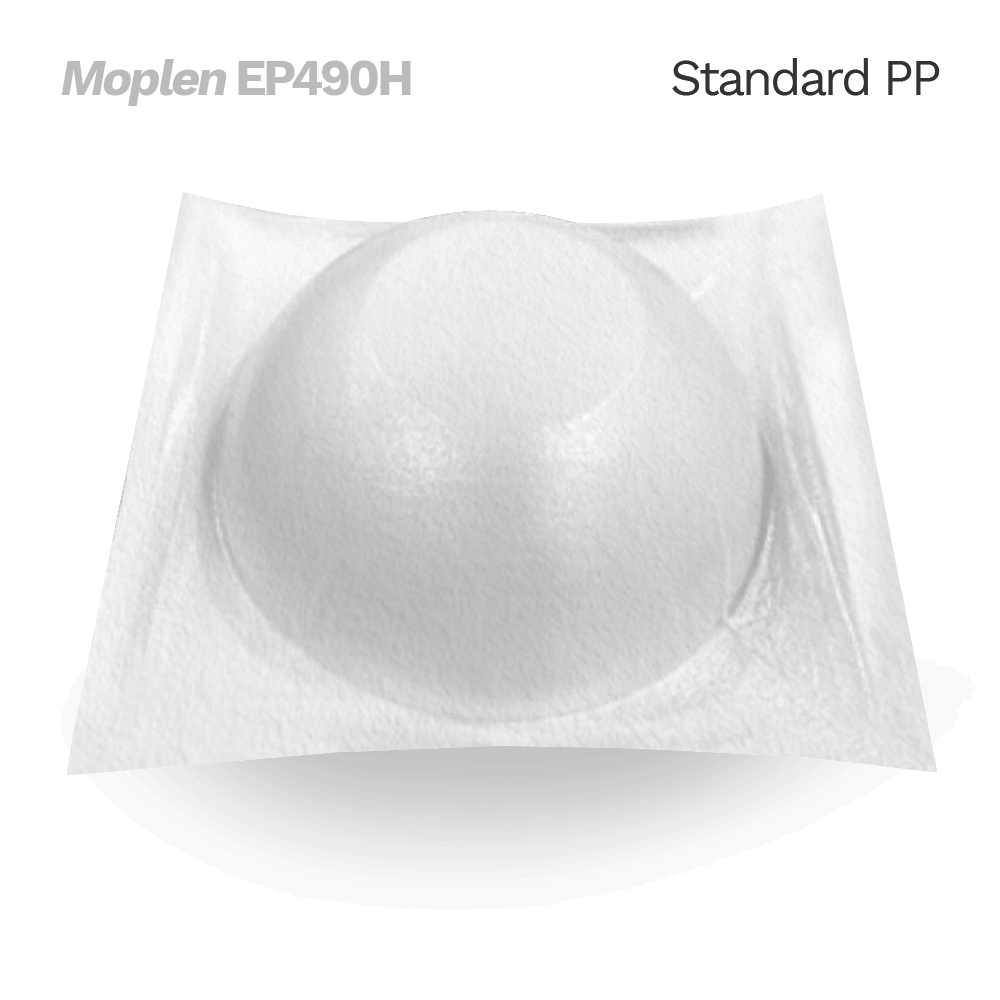

The surface appearance/aesthetics are vastly superior to conventional polypropylene, providing a smooth surface, and increased impact resistance.

Moplen EP490H has fine and uniformed dispersed cell structure, which means it can achieve a much lower density.

The superior foaming properties of Moplen EP490H help reduce the amount of plastic used in production – therefore lowering the carbon footprint and creating a lighter-weight final product.

Moplen EP490H can be used as alternative to EPS. Outstanding dimensional stability and durability make final products re-usable. Mono-material packaging design is possible, making it suitable for existing recycling streams.

Superior foaming reduces density and creates a lightweight / less plastic final product.

Moplen EP490H can be sourced from ISCC PLUS certified feedstock. The use of renewable, bio-based feedstock can significantly reduce carbon footprint vs. products made from fossil-based materials.

Moplen EP490H is produced with a non-phthalate catalyst, is plasticiser and BPA-free, has no residual monomer, and has minimal SML content.

The ingredients and additives used are NON Animal Derived.

Good stiffness, high impact properties at room and sub-zero temperatures, good dimensional stability, water and chemical resistant.

Good stiffness, high impact properties at room and sub-zero temperatures, good dimensional stability, water and chemical resistant.

The ingredients and additives used are NON Animal Derived.

Moplen EP490H is produced with a non-phthalate catalyst, is plasticiser and BPA-free, has no residual monomer, and has minimal SML content.

Moplen EP490H can be sourced from ISCC PLUS certified feedstock. The use of renewable, bio-based feedstock can significantly reduce carbon footprint vs. products made from fossil-based materials.

Superior foaming reduces density and creates a lightweight / less plastic final product.

Moplen EP490H can be used as alternative to EPS. Outstanding dimensional stability and durability make final products re-usable. Mono-material packaging design is possible, making it suitable for existing recycling streams.

The superior foaming properties of Moplen EP490H help reduce the amount of plastic used in production – therefore lowering the carbon footprint and creating a lighter-weight final product.

Choose your service, talk to one of our sales representatives for more details, request a test sample or a quote.

Expanded PP for thermoforming

Roll over for details

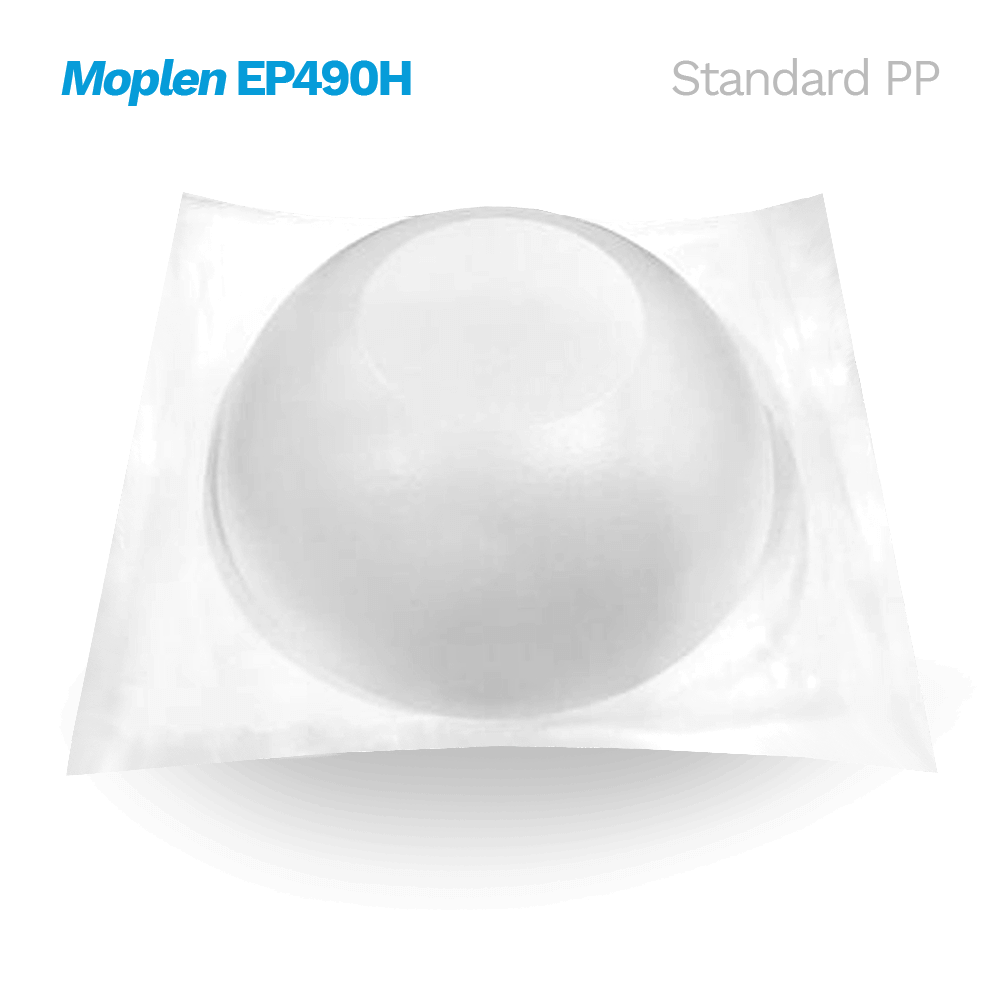

Standard PP

Poor thermoformability, “orange peel” on the surface.

Poorly dispersed cell structure.

Moplen EP490H

Good thermoformability, smooth surface. Fine and uniform dispersed cell structure, achieving a much lower density.

Click on the image for details

Standard PP

Poor thermoformability, “orange peel” on the surface.

Poorly dispersed cell structure.

Moplen EP490H

Good thermoformability, smooth surface. Fine and uniform dispersed cell structure, achieving a much lower density.

Density (g/ml)

Deflection at break (mm)

Impact at break (J)

Density (g/ml)

Deflection at break (mm)

Impact at break (J)

Hot meal and hot drink packaging

* Moplen and Polybatch are trademarks owned and/or used by the LyondellBasell family of companies.

POLYPROPYLENE

Moplen EP490H

MASTERBATCH

We provide the masterbatch for a complete solution:

Polybatch BA 9090 (endothermic blowing agent)

Polybatch CFPP 0260 NU (nucleating agent)

POLYPROPYLENE

Moplen EP490H

MASTERBATCH

We provide the masterbatch for a complete solution:

Polybatch BA 9090 (endothermic blowing agent)

Polybatch CFPP 0260 NU (nucleating agent)

* Moplen and Polybatch are trademarks owned and/or used by the LyondellBasell family of companies.

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |