Dust Free

Novel manufacturing technology limits dust build up in pneumatic conveying systems, facilitating efficient pre-processing of material.

In the steps leading up to the production of components from Nylon 6, there are several scenarios where friction between polymer granules generate dust. If left unchecked, this can lead to dust buildup in your pneumatic conveying and feeding systems resulting in regular maintenance such as frequent changing of air filters and enhanced clean downs. Failure to do so can increase production down time and the risk of quality issues in the final product.

To address this, DOMO have developed a novel solution to overcome this dust issue. Produced using innovative technologies, TECHNYL® C 102 NC DF significantly reduces the presence of micro-particles resulting in a more reliable and efficient production process.

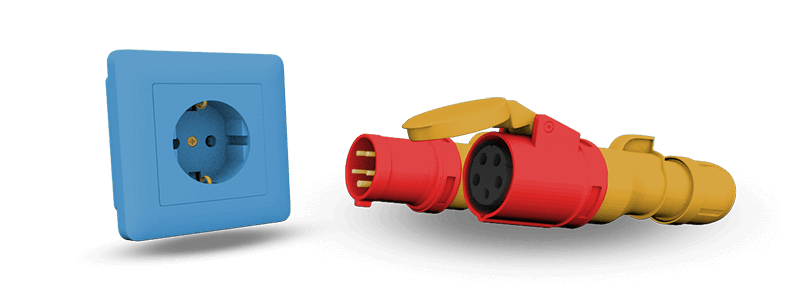

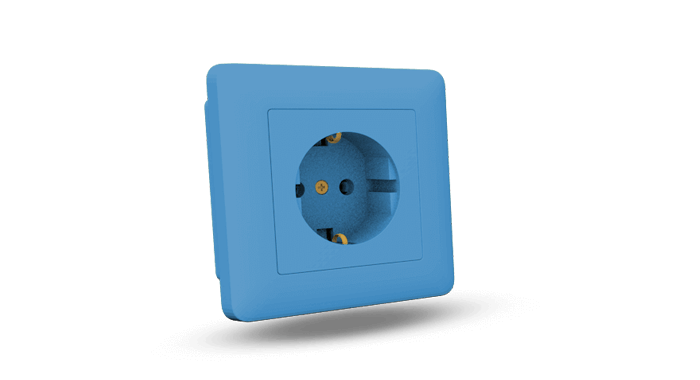

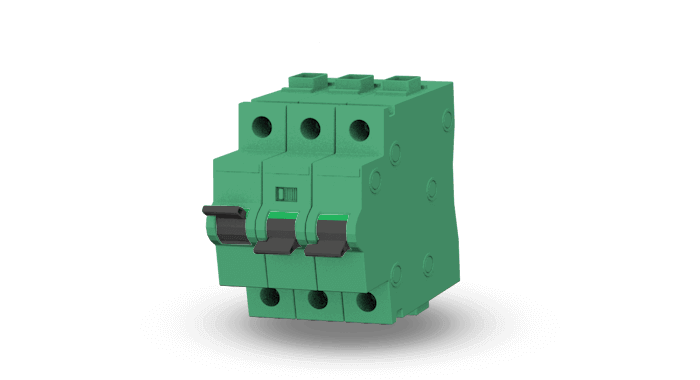

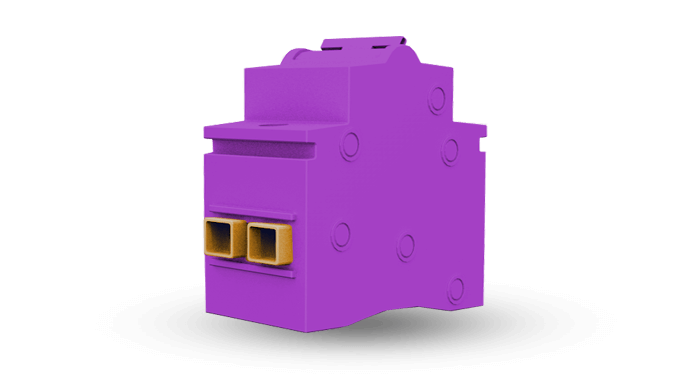

Technyl® C 102 NC DF has been developed for the efficient production of a wide range of electrical components:

Electric plugs

Sockets

Switches

Connectors

Markets & Trends:

Novel manufacturing technology limits dust build up in pneumatic conveying systems, facilitating efficient pre-processing of material.

Reduced cycle times for efficient production through improved flow and optimised processing.

Tailored FR packages from V2 to V0, GWFI 850-960oC and thicknesses down to 0.4 mm.

Colour solutions via compound or masterbatch technology, whilst retaining UL approvals* (UL certified masterbatches required).

Extensive certification ensuring high confidence in the safety and performance of your products. Including Yellow Cards and International Standards.

Good mechanical properties supporting use in a broad range of applications and assembly methods (snap-fit and push-fit fixings).

Novel manufacturing technology limits dust build up in pneumatic conveying systems, facilitating efficient pre-processing of material.

Reduced cycle times for efficient production through improved flow and optimised processing.

Tailored FR packages from V2 to V0, GWFI 850-960 oC and thicknesses down to 0.4 mm.

Colour solutions via compound or masterbatch technology, whilst retaining UL approvals* (UL certified masterbatches required).

Extensive certification ensuring high confidence in the safety and performance of your products. Including Yellow Cards and International Standards.

Good mechanical properties supporting use in a broad range of applications and assembly methods (snap-fit and push-fit fixings).

Learn more about TECHNYL® C 102 NC DF’s enhanced processability with expert guidance from Florence Schutz, C&E Segment Manager at DOMO.

Take advantage of the opportunity to get ahead in the E&E industry.

Act now for long-term success!

Choose your service, request a test sample or a quote. We will respond shortly.

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |